PE 100 PIPE TS EN 12001 – 2 + A1

HDPE 100 PIPE PROPERTIES

The raw material ‘ polyethylene ‘ formed after polymerization of ethylene gas obtained from oil has also been used in the production of plastic pipes.

PE 63, PE 80 and PE 32 were used in drinking water network lines for the first time in the early 1950's with the developing technology of polyethylene as the environmental stress value and density was low.

Finally, in 1990 th PE 100 model became the most preferred product in pressurized lines, low economy and high performance.

PE 100 pipe corrosion, not affected by chemicals, wear resistance is high makes life advantageous compared to alternative products.th There is no need for cathodic protection since it is not affected by harmful substances in the soil structure that have an etching effect. The minimum service life of PE 100 pipe is 50 years.

PE 100 pipe, which is very high thawing ability according to rigid lines in earthquake and erosion events, absorbs opening by extending 350% -600% break through ability.

PE 100 pipes that maintain elastic properties up to -40 °C are not affected by water thawing into ice. While steel pipes react by splitting into these transformations, PE 100 th pipe expands and absorbs volume increase.

PE 100 can be used in submerged submarines as well as thawed and used in river lakes and sea crossings , not affected by sea water and sea movements.

PE 100 pipe can be curled with a radius of 20-35 times th of its diameter at turns, saving additional parts usage.

It is not affected by coach impacts which cause pressure class to rise in rigid pipes.

It is resistant to UV rays from sun since it is produced by Carbon Black additive.

In PE pipe networks, the safety coefficient is determined according to the class of the raw material and the state of the network, and all calculations are made according to THC coefficient.

In natural gas networks, the safety coefficient is C=2.0 and in drinking water transmission lines, the safety coefficient is C=1.25.

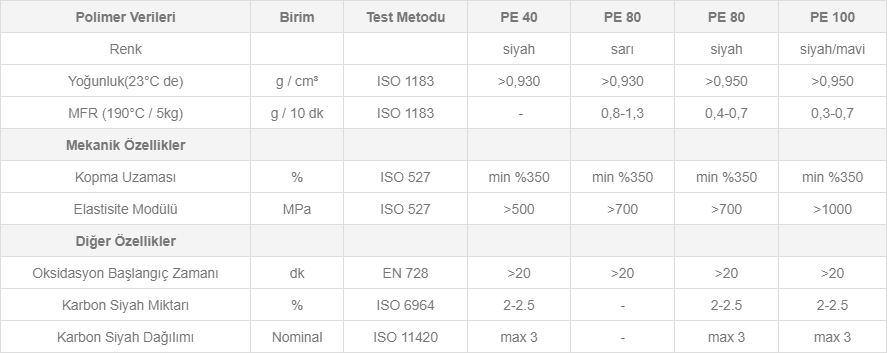

RAW MATERIAL PROPERTIES

HDPE 100 PIPES USAGE AREA

- Underground drinking water lines

- Aboveground drinking water lines

- City network lines

- Sewer lines

- Hot & cold water lines,

- Steam lines

- Natural gas lines

- Geothermal systems

- Fire water lines

- Drainage lines

WEIGHT CHART

HDPE 100 PIPE FITTINGS

The fittings of HDPE 100 pipes are classified according to different production methods. From the extruder machine, which is the production machine, to the products that come out in one piece; Injection Fittings can be welded from pipes to products prepared by joining; Garment Attachments, Products produced for use in electrofusion welding are called EF fittings, products with threaded connection nipples are called Coupling fittings.